Case Study for PCI Measurement at Airport

Introduction

In the modern world, airports play a significant role in the development of any region. They not only move people but also facilitate tourism, generate employment, increase revenue from taxation, and foster the conservation of protected areas.

Figure 1: Airport Considered for Pilot Study

In Asia, due to high population density, most of the airports have a single runway (barring major ones which have two). Bali airport in Indonesia is one of the busiest airports the South East Asia, having 600 landings in a day, runs operation on a single runway. In such a scenario, maintenance of the runways’ pavement surfaces (Apron, Taxiway and Runway) becomes a challenging task as any failure leads to huge financial loss and also results in the halting of entire operations.

The Challenge

The challenge in working on airports in Asia is that they are operational 24×7, leading to small window for maintenance work. Need of the hour is to have a

system which is very effective in functioning and has less turnaround time (data should be collected and processed rapidly)

As per ASTM D 5340 standards, Pavement Condition Index (PCI) is one of the parameters which should be evaluated at frequent intervals which indicates the strength of the pavement. The key to pavement evaluation is to identify different types of pavement distress and link them together. This process helps in understanding the current condition holistically along with historic rate of deterioration which helps in developing appropriate maintenance and rehabilitation plans.

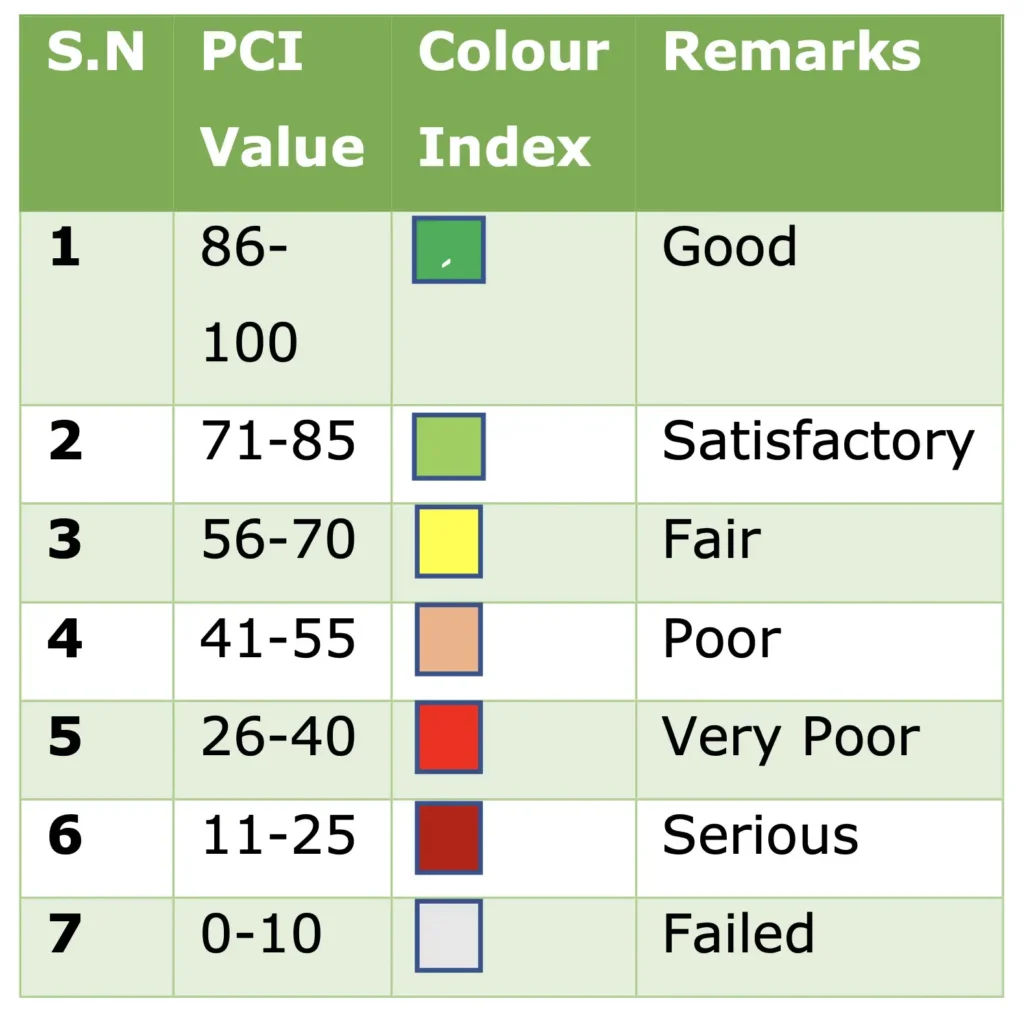

Table 1: index used for defining PCI

The Solution

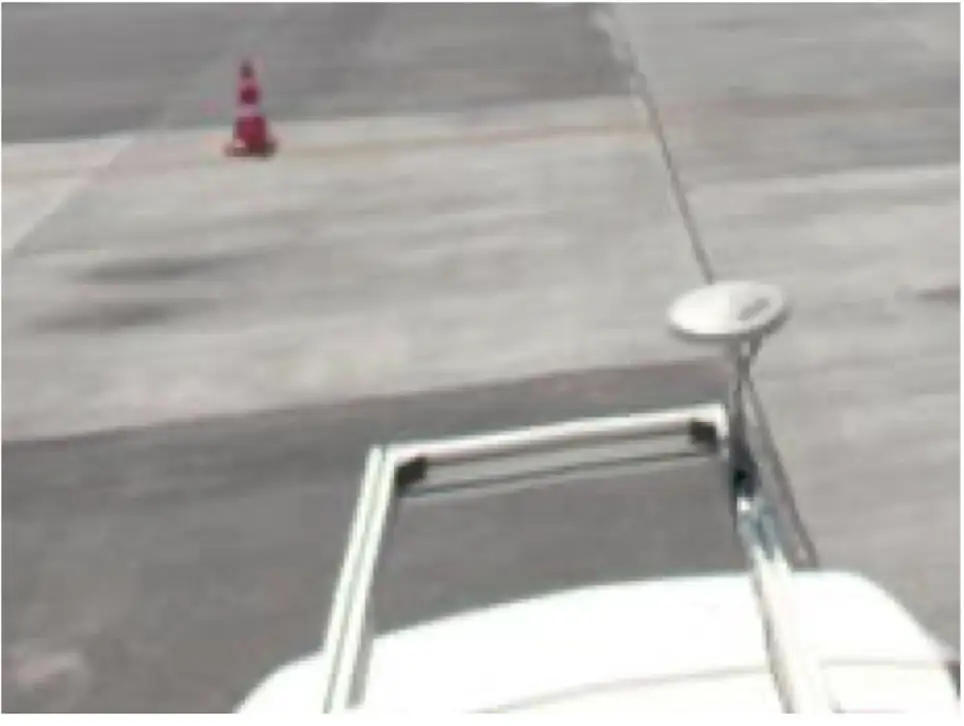

The airport considered for this study is one of the busiest in India, hence it was not possible to scan the entire area. Sample scanning was done on all the 3 pavement types viz. Apron (Parking bay), Runway (the surface on which aircraft takes off / land) and Taxi Way (surface connecting Apron to Runway). In this study for each type pf pavement, two samples were collected. Average sample size was 800m– 1200m length x 4m width. Usually in Asian countries surface type for Apron is Concrete (rigid) whereas for Runway and Taxiway its Asphalt (flexible).

The entire process is described in brief below:

– Homogeneity

– IRI (Roughness index) and MPD (Mean Profile depth)

– Photo structure (for aligning the photo’s)

– Crack / pothholes

– Pavement Structure (contains Rutting, Longitudinal profile, cross fall,

curve radius etc)

Cracks

Bad Joints

Patch Work

By using combination of homogeneity / point cloud and photographs we were able to mark all surface distresses which are essential for calculating PCI

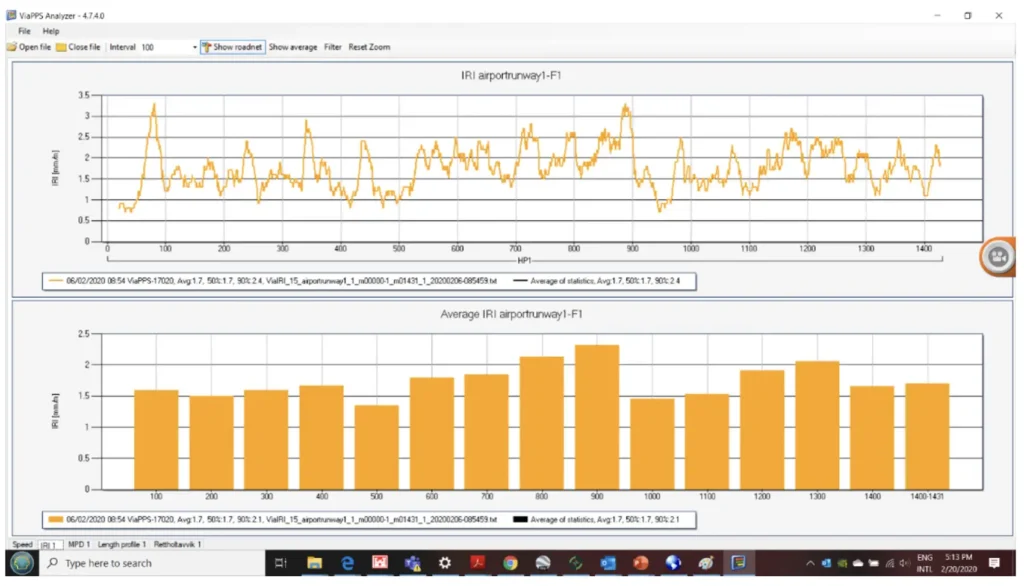

Figure 1: Sample report generated for IRI (roughness index)

The best part of entire process is the speed at which data capture and processing is done. If all sections are made available, the entire airport can be scanned in two hours with processing and reporting taking another two hours. For the pilot airport, we completed six sections in less than an hour.

The Result

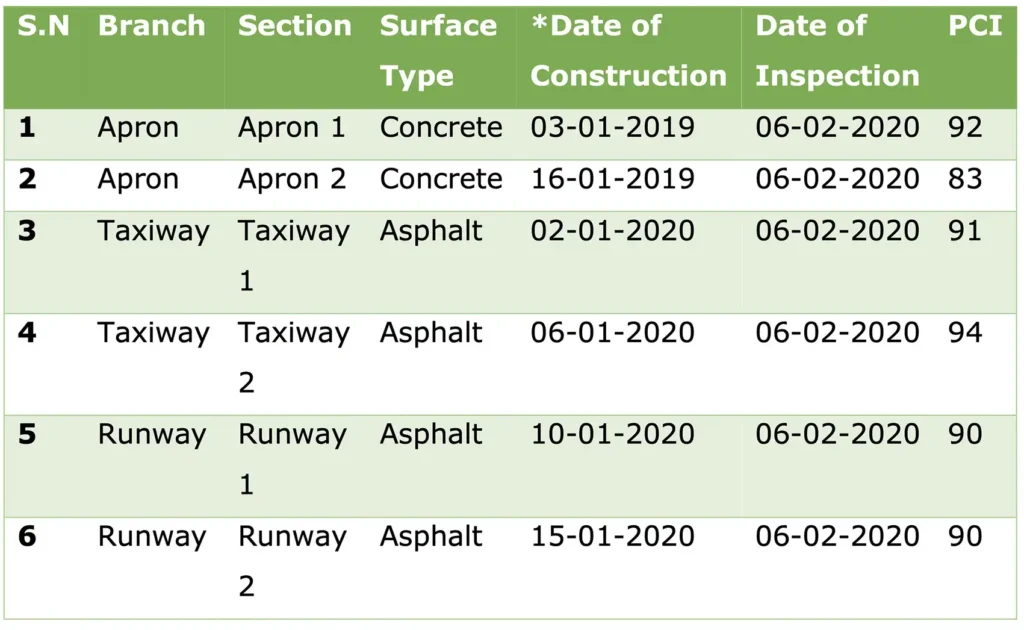

The PCI values calculated from the study are as indicated below.

Network Name : Airport

The samples were taken from a newly laid surface in the airport; hence the PCI was in the good category overall. However, to monitor the surface and carry out preventive maintenance, its required that airport should be scanned once a week to identify the grey area’s and to carry out monitoring at the finest level as possible.

Tools Used

ViaPPS (Pavement Scanner)

This is inhouse technology developed by ViaTech AS, Norway (www.viatech.no) The main application of ViaPPS is for pavement maintenance and safety. ViaPPS has multiple sensors that captures various parameters like cracking, rutting, raveling, bleeding etc., which defines the surface distress. The entire pavement maintenance schedule can be planned based on this data. Using this equipment, any sort of distress can be captured at even the most initial levels. Norwegian road authority has been using this system for the last 12 years for maintaining their highway.

For more information check on http://viatech.no/products.aspx?lang=en&id=6

Paver

Paver is software developed by US Army Corps of Engineers and Federal Aviation Administration. This software is developed on ASTM standard ASTM D6433 for highways and ASTM D5340 for airports.

For more information check on http://www.paver.colostate.edu/